Emergency Action Plan

SAFETY REQUIREMENT

Procedures to be followed by employees who remain

to operate critical plant operations before they

evacuate;

Procedures to account for all employees after evacu-

ation;

Procedures to be followed by employees performing

rescue or medical duties; and

The name or job title of every employee who may be

contacted by employees who need more infor-

mation about the plan or an explanation of their

duties under the plan.

Although not specifically required by OSHA, it may be

helpful to include the following:

A description of the alarm system to be used to notify

employees (including disabled employees) to

evacuate and/or take other actions. The alarms

used for different actions should be distinctive and

might include horn blasts, sirens, or even public

address systems.

The site of an alternative communications center to

be used in the event of a fire or explosion.

A secure on- or offsite location to store originals or

duplicate copies of accounting records, legal docu-

ments, your employees' emergency contact lists, and

other essential records.

Complete Workplace Evaluation

Warning system:

Warning alarms are installed.

Employees are trained to correlate signal patterns

with specific types of emergencies.

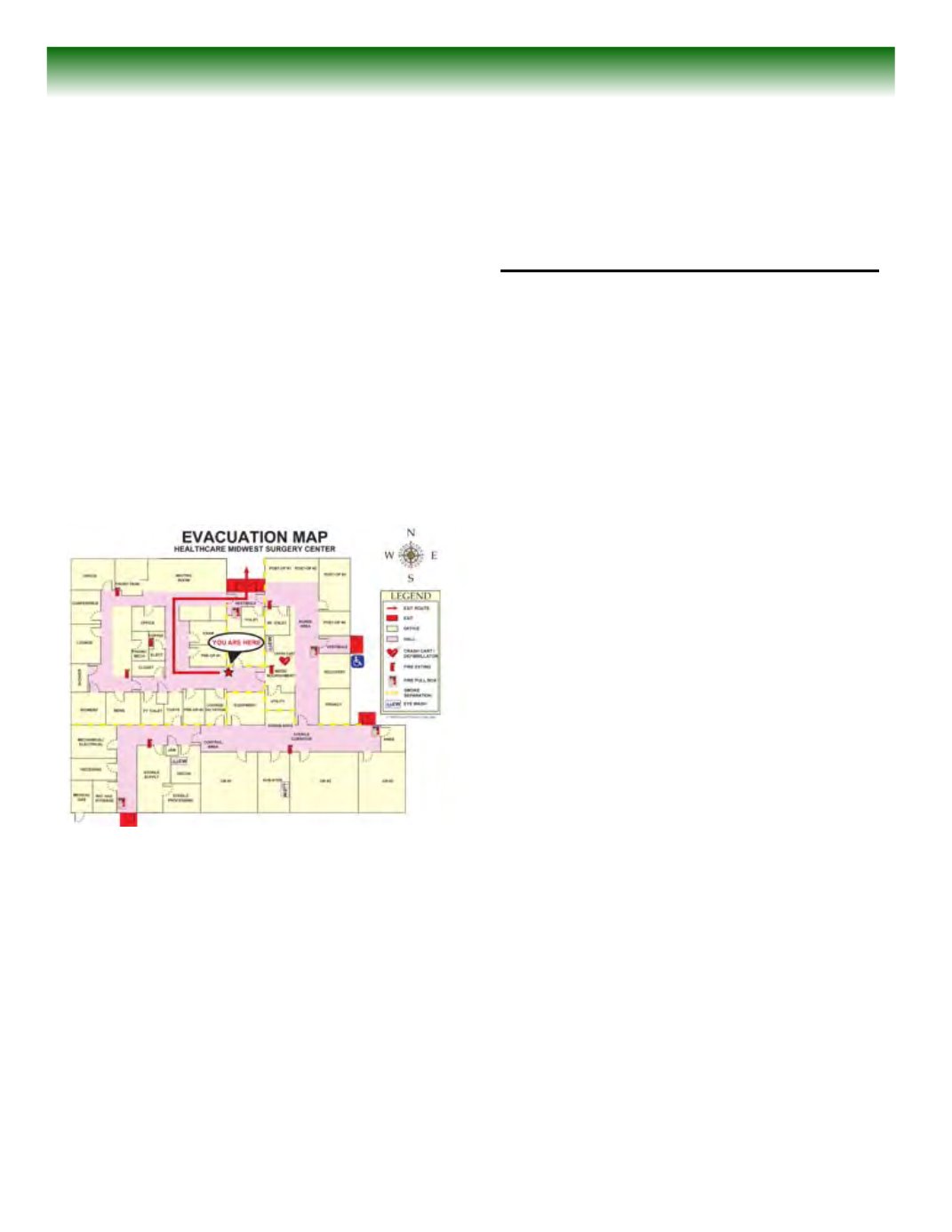

Exist Routes:

Exit Route are established.

Exit routes are marked.

Exit signs are over doorways

Exit Route Maps are posted at the facility.

Employees are trained on exit routes.

Fire Prevention Plan:

A Fire Prevention Plan is in place.

Potential fire fuel sources are identified:

Fuel storage area; gasoline or diesel.

Used Oil storage area.

Vehicles storage areas.

Shop floor with spills and/or absorbent ma-

terial.

Battery storage area.

Cutting torch use area.

Building systems.

Fire suppression system.

Fire alarms.

Smoke detectors.

Employees are trained on the Fire Prevention

Plan.

Portable fire extinguishers:

Fire Extinguishers are in place and appropriately

mounted.

Signage identifies fire extinguisher loca-

tions.

Fire extinguishers are checked annually by a pro-

fessional.

Fire extinguishers are checked monthly by

the Safety Supervisor.

Fire extinguishers are tested and refur-

bished at least every five years.

Annual fire extinguisher employee training is

conducted.

Employees practice the PASS system during

training.

Page 13

Recyclers News Press